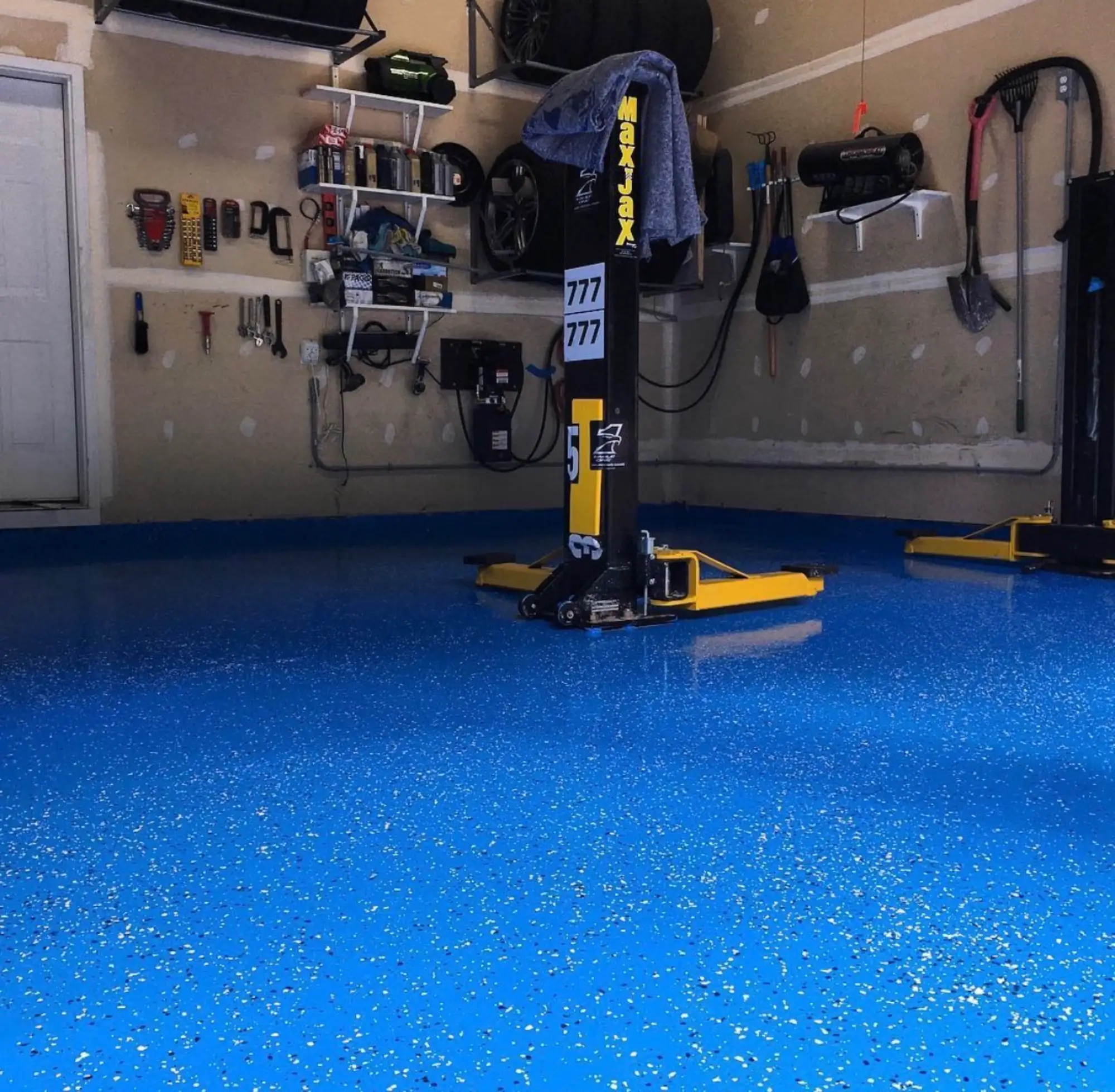

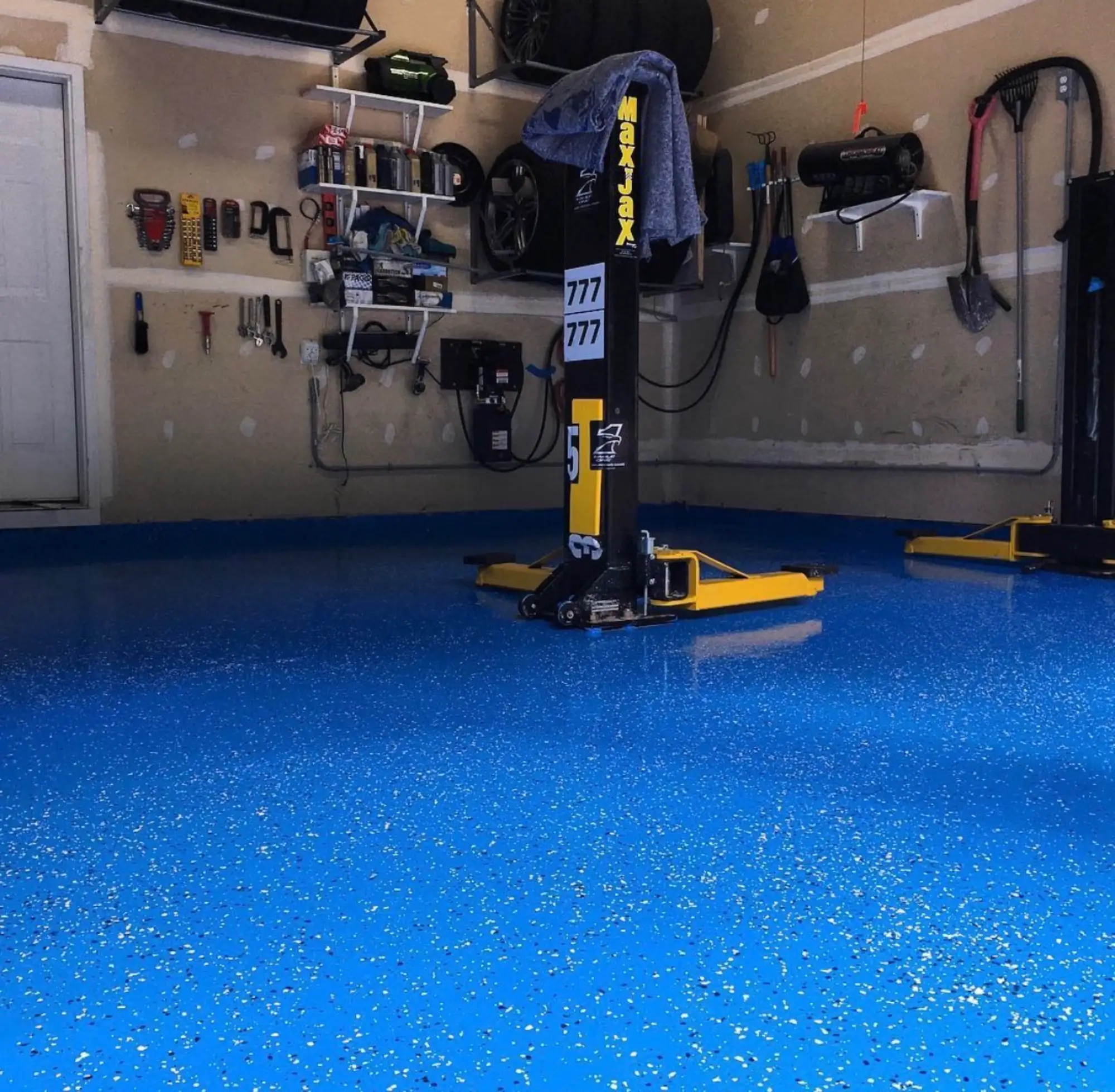

Brunswick Epoxy Contractors and Garage Floor Coatings

Add durable and attractive epoxy to your garage, basement, patio, commercial space and more.

Epoxy flooring often gets presented as a straightforward project, but in practice, it's really more like a system. The condition of the concrete, how moisture seeps through the concrete slab, the way the surface is prepared, and when the material is applied all affect how the floor holds up later. Hoplite Construction installs epoxy flooring throughout Brunswick and Sagadahoc County, and rather than treating epoxy as a quick cosmetic add-on, we view it as a way to add function to your home for years to come. We respond to new inquiries within 24 hours and provide free quotes in five days or less. If you are considering epoxy for a garage, basement, or commercial space, get in touch.

Free quotes in five days or less

24-hour response to new inquiries

Certified composite technician oversight

You Need an Epoxy Flooring Specialist

Epoxy behaves very differently from paint or surface coatings since it bonds to concrete and cures through a chemical reaction. There is a lot that can go wrong for those without experience. Surface profile, moisture levels, ambient temperature, and mixing ratios all play a role, and problems often show up long after the floor initially looks fine. At Hoplite Construction, epoxy floors are installed by trained tradespeople who work to commercial construction standards. A certified composite technician oversees the system, which means preparation, material handling, and cure timing are treated as technical requirements rather than optional steps. That oversight is what allows the finished floor to hold up under daily use instead of slowly breaking down.

The Epoxy Flooring Installation Process

Every epoxy flooring project follows our proven process ensuring clear communication, proper preparation, and long-lasting results from site evaluation through final cure.

- Step 01

Site Evaluation and Surface Assessment

Every epoxy project begins with the concrete itself. We look at how the slab was poured, how it has been used, and what it has been exposed to over time. Moisture migration, joint movement, and surface wear all tell a story about what the floor needs to perform well. A garage that sees road salt and seasonal temperature swings behaves very differently from a basement or a small commercial space. Understanding those differences early helps us avoid installing a technically sound system in a space where it does not truly belong.

- Step 02

Detailed Quote

After the scope is clear, we put together a quote that reflects what the job actually requires, not what looks good on paper. Surface grinding, crack repair, moisture control, material selection, and topcoat protection are all accounted for up front. We also walk through timing so you know when the space will be offline and when it can be used again. Epoxy does not like to be rushed, and cure time is built into the schedule rather than treated as an inconvenience.

- Step 03

Mechanical Prep and System Installation

Surface preparation does most of the heavy lifting in epoxy performance. We mechanically grind the concrete to achieve the right profile for adhesion, address cracks and joints, and resolve moisture issues before material is applied. The epoxy system is then installed in layers, each serving a specific function within the overall build. A protective topcoat completes the system and adds durability and traction where needed.

- Step 04

Final Cure and Turnover

Once the system is installed, the floor is left to cure under conditions that support long-term performance. Rushing this phase undermines the work done earlier. After cure, we review the surface for uniformity, confirm coverage, and talk through how the floor should be cared for so it continues to perform the way it was designed to.

* We provide free quotes in five days or less and respond to new inquiries within 24 hours.

Every Aspect of Your Epoxy Floor Considered and Executed

From residential garages to commercial spaces, we handle every detail of your epoxy flooring project with the same level of care and expertise.

Residential Epoxy Flooring Applications

01In homes, epoxy tends to make the most sense in spaces that see wear, mess, or moisture and where traditional finishes struggle to hold up. Garages, basements, workshops, and home gyms are common examples. When installed properly, epoxy creates a sealed surface that resists staining, handles impact, and cleans easily. Many homeowners choose epoxy not for appearance alone, but because it turns underused or unfinished areas into spaces that feel intentional and usable.

Commercial and Light Commercial Spaces

02Epoxy flooring is also a practical choice for small commercial environments where floors need to tolerate traffic, equipment, and frequent cleaning. Service areas, workrooms, retail back spaces, and utility zones all benefit from a surface that does not break down under regular use. Our commercial epoxy systems are selected with those demands in mind and installed using methods aligned with commercial expectations rather than residential shortcuts.

Certified Composite Technician Oversight

03Epoxy installation involves chemistry as much as craftsmanship. Mixing ratios, pot life, application windows, and cure conditions all influence whether the system bonds as intended. With certified composite technician oversight, those variables are managed deliberately throughout the installation, reducing the chances of problems that tend to surface months or years later.

Durability, Safety, and Finish Options

04Hoplite epoxy systems are built to take abuse without losing their footing or appearance. Impact resistance, chemical resistance, and surface traction are addressed during system selection rather than after the fact. Non-slip textures are added where footing matters, and color or flake options are chosen to suit the space instead of overpowering it. The result is a floor that prioritizes performance while still looking finished.

Long Term Performance and Maintenance

05Once installed, epoxy floors are relatively easy to keep up with. The sealed surface does not absorb spills, and routine cleaning keeps it looking consistent. Compared to thin, store-bought products, professionally installed epoxy systems tend to last longer and demand less ongoing attention.

Start Your Project Today with Us

Don’t wait for weeks—our teams respond quickly, deliver quotes within 5-days of a site visit, and get your renovation project moving with maximum precision and minimal hassle.

What Our Clients

Say About Us

An outstanding and affordable service was provided in a timely manner

Brian C.I was worried about the ice taking off my gutter but the team accounted for that so the snow and ice didn't phase it.

Faith M.The company ensured my gutter color matched perfectly with my house.

Brenda R.

Epoxy Flooring FAQs

Cost depends on the size of the space, the condition of the concrete, and the type of system required. Residential garage floors often begin in the low thousands, while larger areas or slabs that need extensive preparation or moisture mitigation will fall higher. Commercial spaces are priced based on use demands and system thickness. A walkthrough allows us to provide pricing that reflects real conditions rather than assumptions.

Failures usually trace back to inadequate surface preparation, unresolved moisture issues, or incorrect mixing and cure conditions. Without mechanical grinding and proper testing, adhesion problems are common even when the floor looks acceptable at first.

Most epoxy floors are installed over one to three days, depending on size and prep requirements. Cure time varies by system, and we schedule projects so the space can return to use safely.

Epoxy can feel slick when smooth, but non-slip additives are available and commonly used in garages, basements, and commercial settings.

Cracks and joints can often be repaired prior to installation. The condition of the slab determines what preparation is required, which we evaluate early.

Moisture must be addressed before epoxy is installed. We test for moisture and use mitigation methods when needed to protect adhesion.

With proper installation and normal use, professional epoxy systems last many years. Traffic level, maintenance, and system choice all influence longevity.

Yes. We offer a range of color and flake styles that allow the floor to look finished without sacrificing durability.

Routine sweeping and occasional mopping are usually sufficient. The sealed surface resists staining and does not absorb spills.

Hoplite Construction installs epoxy flooring in Brunswick, throughout Sagadahoc County, and surrounding midcoast Maine communities.

Call Your Local Epoxy Flooring Installers Today

If you are considering epoxy flooring and want a system that holds up under real use, reach out to Hoplite Construction. We respond within 24 hours and provide free quotes in five days or less. A site evaluation is the right place to begin.